- Top: 3731Step on: 197

mig welding ventilation

People involved | Date:2025-08-16 17:30:53

Related articles

Investing in automatic spray painting machines is not just about improving production processes—it’s also a strategic move for long-term profitability. These systems reduce labor costs, enhance product quality, and optimize resource utilization, providing a significant return on investment.

The future of robotic welding arms appears promising, with continuous advancements in artificial intelligence, machine learning, and automation technology. These innovations will enable robotic welders to perform even more complex tasks and operate collaboratively alongside human workers. As industries push towards Industry 4.0, the integration of robotics into manufacturing processes will become increasingly essential.

Get Started with Yeed Tech Co., Ltd. Today!

An automatic spraying line is designed to automate the coating process, ensuring uniform application of paints and finishes across a variety of surfaces. This technology is especially critical in industries where precision and consistency are non-negotiable, such as automotive manufacturing, furniture production, and electronics.

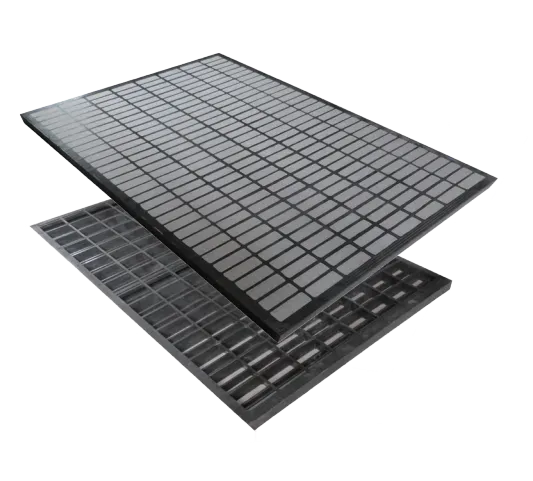

- Bridges Given their strength and durability, steel floor systems are extensively used in bridge construction, supporting heavy vehicle traffic and ensuring longevity.

4. After-Sales Service Ongoing support does not end with the purchase of equipment. A reliable manufacturer will offer maintenance services, spare parts, and upgrades, ensuring that the equipment remains efficient over time.

Conclusion

Conclusion

For larger operations or fixed welding stations, wall mounted fume extractors offer an efficient and space-saving solution to managing welding fumes. These systems can be strategically placed to capture smoke at the source, preventing it from spreading throughout the facility.

Conclusion

Comment area